Equipment parameters– laser: red light, cold light (optional)

– circuit board size: minimum 50mm * 50mm, maximum 400mm * 300mm (customizable)

– circuit board thickness: 0.6-4mm

– repetitive positioning accuracy: ± 0.02mm

– minimum line width: < 0.005mm

– support barcode types: code128, code39, ean-8, UPC-A and other barcodes, DataMatrix, QR and other QR codes

– board entry mode: left in right out, right in left out (optional)

– working platform: X-Y linear module

– positioning system: paraxial CCD camera

– external auxiliary device: negative pressure adsorption dust extraction system

– power protection (optional): UPS, continuous operation for 10 minutes after power failure

– power supply specification: 220V / 50Hz / 2KW

– gas supply specification: 0.6MPa

– environmental requirements: 5-35 ℃, humidity less than 50%

– overall size: 1050mm * 1150mm * 1700mm

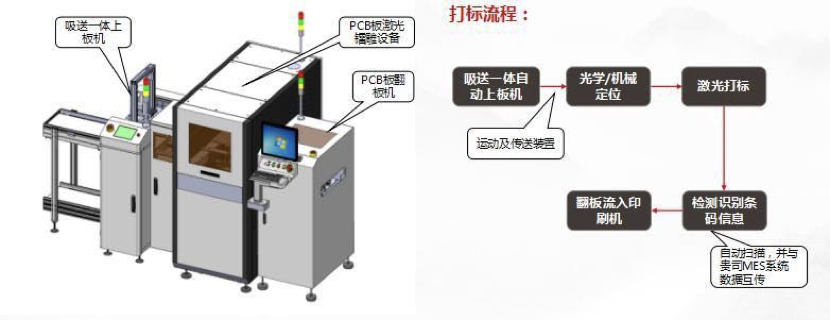

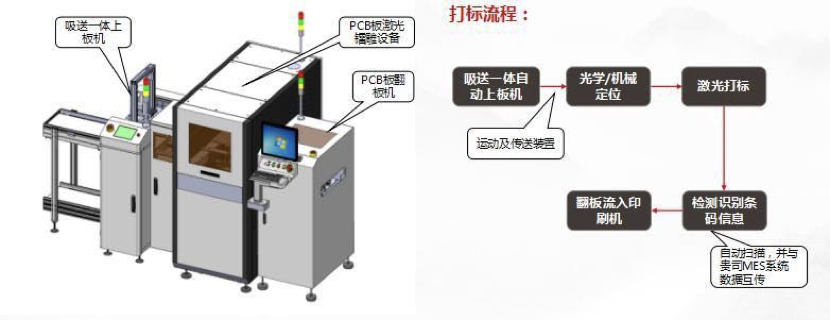

Equipment features:1. Servo XY motion platform, industrial PC control, modular and flexible programming design.

2. Standard green laser (other lasers can also be selected), which can engrave a QR code of 1.6mmx1.6mm up to 16 characters at least.

3. Coaxial CCD technology, precise positioning, reading and identifying two-dimensional code level (applicable to aim DPM, as9132 and other standards).

4. Three color light source illumination: the color can be switched in three colors, which is convenient for reading the engraving marks of different color plates.

5. The conveyor belt is 900 ± 30mm from the ground and can be directly connected to SMT. The direction of feeding and discharging movement can be selected.

6. Standard SMEMA interface and network communication function, which can communicate with upstream and downstream equipment and servers;

7. Dust filter device can effectively remove the dust generated during marking to ensure cleanness and health.

8. Take the initiative to prevent stupidity, and the software will automatically detect and prevent wrong and missed typing; The main door is equipped with safety switch lock, which is controlled by software,

9. No legal person is allowed to open all doors during the engraving process to prevent defective products;

10. The inlet and outlet are equipped with automatic shielding doors to prevent strong light from damaging human eyes during laser engraving

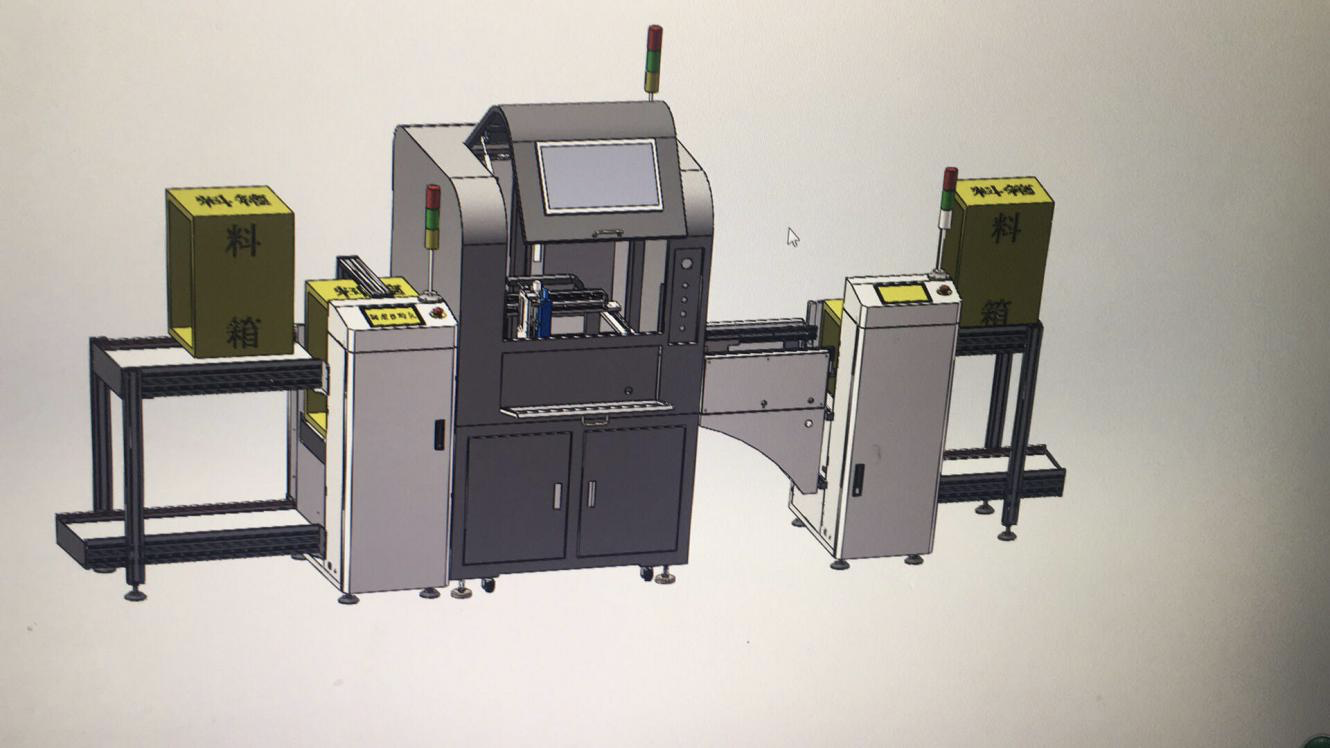

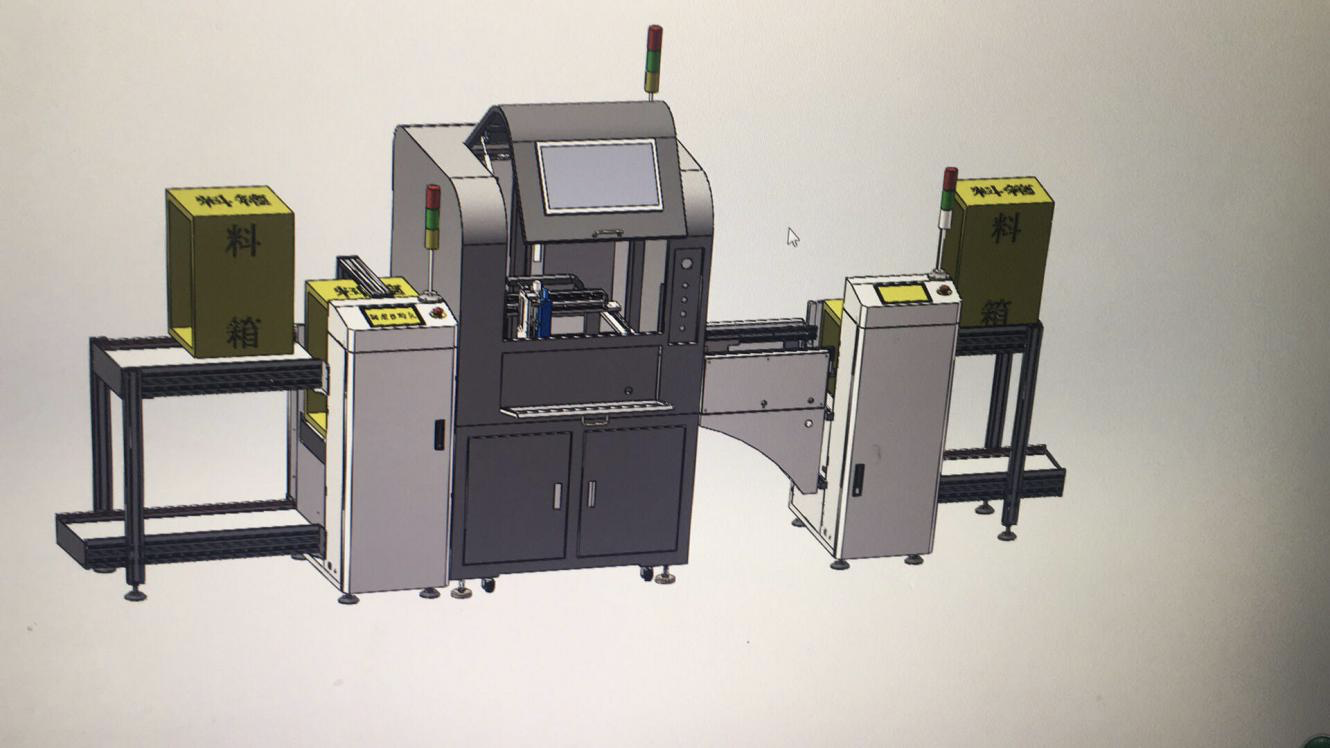

It is a special equipment for sorting and counting different types of OK / ng boards before PCB packaging. The single chip identification time is 1.2-4s, and the capacity is 1k-3k pieces / hour. It can identify numbers, letters, bar codes, two-dimensional codes, etc

Sample test and rendering

1: The green oil surface is directly marked with bar code and two-dimensional code (no copper leakage, clear and easy to read)

2: Spray white paint on the green oil surface to mark two-dimensional code (no copper leakage, clear and easy to read)